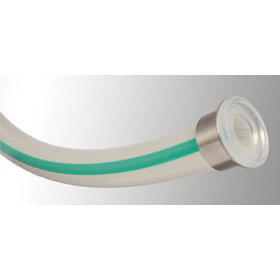

Zero liquid accumulation! Heat-resistant, food-grade hose fitting integrated molding.

Hose and fittings are integrated! There is zero step between the hose and fittings! With no nipple, there is zero step between the hose and fittings! No worries about liquid pooling! FDA registered.

The hose and fittings are integrally molded from the same material, silicone. Traditionally, stainless steel fittings were used, requiring disassembly for cleaning, but this product is nipple-less, eliminating the need for disassembly and cleaning. This reduces time and improves hygiene. Since the ferrule part is also made of silicone, gaskets that were previously necessary are no longer needed. There is no risk of gaskets falling during the connection of fittings, which enhances workability and eliminates the risk of foreign matter contamination.

- Company:トヨックス 東京支店、名古屋支店、大阪支店

- Price:Other